MHJF Robot Operator Certification

The Fundamentals of Robotics course exposes participants to the essentials of robotics theory and certifies them for the operation of the MHJF robotic arm and FS100 controller.

Throughout the course, students learn how to perform skills such as manipulating the robot, creating basic motion programs, resolving errors, defining coordinate systems, outlining interference areas and programming and interacting with the RoboCell robotic simulation software. Most of the course content is presented in the form of classroom activities (referred to simply as “activities”) and laboratory activities (“lab activities”). Both of these terms will be defined in the sections below.

The course concludes with a practical exam, which the students must pass to obtain Motoman Operator Certification. Candidates that successfully complete the practical exam are then eligible to take the final certification exam, which is a test composed of 40 multiple choice questions about the Motoman system and robotic theory.

Maintenance Technicians use mathematics as an integral part of their everyday activities such as installing, maintaining, and troubleshooting equipment. Through virtual activities, Math for Technicians 1 delivers the mathematics and physics skills needed for working with materials, maintaining machinery and creating equipment layouts. (Course 1 of 16 for the MSSC CPT Prep Training)

Maintenance Technicians use mathematics as an integral part of their everyday activities such as installing, maintaining, and troubleshooting equipment. Through virtual activities, Math for Technicians 1 delivers the mathematics and physics skills needed for working with materials, maintaining machinery and creating equipment layouts. (Course 1 of 16 for the MSSC CPT Prep Training) The Mechanical Fasteners course includes twelve activities allowing students to identify and work with many types of fasteners used in engineering and industrial environments. (Course 2 of 16 for the MSSC CPT Prep Training)

The Mechanical Fasteners course includes twelve activities allowing students to identify and work with many types of fasteners used in engineering and industrial environments. (Course 2 of 16 for the MSSC CPT Prep Training)  Hand tools play a key role in the everyday tasks of engineers, electrical technicians and other skilled professionals. Hand Tools features skills-based curriculum delivered through seventeen activities in which students learn all aspects of using hand tools. (Course 3 of 16 for the MSSC CPT Prep Training)

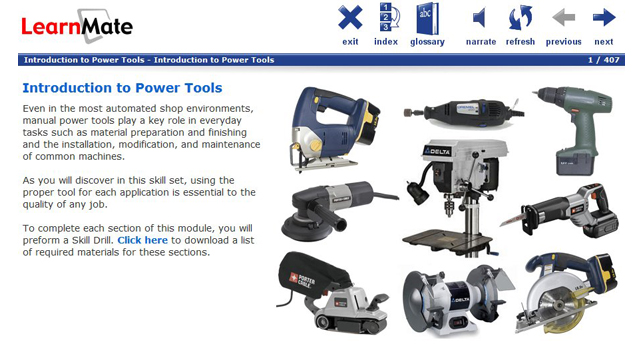

Hand tools play a key role in the everyday tasks of engineers, electrical technicians and other skilled professionals. Hand Tools features skills-based curriculum delivered through seventeen activities in which students learn all aspects of using hand tools. (Course 3 of 16 for the MSSC CPT Prep Training) Power tools play a key role in the everyday tasks of engineers, electrical technicians and other skilled professionals. Power Tools delivers twelve skills-based activities, in which students learn all aspects of using power tools. (Course 4 of 16 for the MSSC CPT Prep Training)

Power tools play a key role in the everyday tasks of engineers, electrical technicians and other skilled professionals. Power Tools delivers twelve skills-based activities, in which students learn all aspects of using power tools. (Course 4 of 16 for the MSSC CPT Prep Training) The Safety Fundamentals course introduces students to

important safety fundamentals regarding regulations, policies, equipment,

procedures, training and much more. After providing information

on safety, the course then covers training, production team member roles,

product development and customer service. (Course 5 of 16 for the MSSC CPT Prep Training)

The Safety Fundamentals course introduces students to

important safety fundamentals regarding regulations, policies, equipment,

procedures, training and much more. After providing information

on safety, the course then covers training, production team member roles,

product development and customer service. (Course 5 of 16 for the MSSC CPT Prep Training) Lockout/tagout procedures are critical in creating a safe work environment. Through interactive activities, students learn all aspects of lockout/tagout procedures in industrial environments. (Course 6 of 16 for the MSSC CPT Prep Training)

Lockout/tagout procedures are critical in creating a safe work environment. Through interactive activities, students learn all aspects of lockout/tagout procedures in industrial environments. (Course 6 of 16 for the MSSC CPT Prep Training) The Employability course was developed in conjunction with SkillsUSA to prepare high school and college students with the skills required to apply for, and succeed in their first job. The course covers job application topics such as setting career goals, résumé preparation and interview skills. (Course 7 of 16 for the MSSC CPT Prep Training)

The Employability course was developed in conjunction with SkillsUSA to prepare high school and college students with the skills required to apply for, and succeed in their first job. The course covers job application topics such as setting career goals, résumé preparation and interview skills. (Course 7 of 16 for the MSSC CPT Prep Training) Mathematics for Technicians 2 applies advanced mathematics concepts to everyday tasks. Through interactive activities students learn about drive ratios, Ohm’s Law, mechanical principles, and how these concepts apply in the engineering and industrial environments. (Course 8 of 16 for the MSSC CPT Prep Training)

Mathematics for Technicians 2 applies advanced mathematics concepts to everyday tasks. Through interactive activities students learn about drive ratios, Ohm’s Law, mechanical principles, and how these concepts apply in the engineering and industrial environments. (Course 8 of 16 for the MSSC CPT Prep Training) Blueprint Reading delivers skills-based curriculum through virtual activities. Students learn all aspects of reading and interpreting blueprints in engineering and industrial environments, including views, tolerances, cutting planes, thread dimensions, and welding symbols. (Course 9 of 16 for the MSSC CPT Prep Training)

Blueprint Reading delivers skills-based curriculum through virtual activities. Students learn all aspects of reading and interpreting blueprints in engineering and industrial environments, including views, tolerances, cutting planes, thread dimensions, and welding symbols. (Course 9 of 16 for the MSSC CPT Prep Training) The Mechanical Measurement and Quality Control module enables students to gain a solid foundation of knowledge and skill in performing measurements and calculations. The student learns to use precision measurement tools, such as steel rule, tape measure, protractor, micrometer, height gauge, various calipers and dial indicators.

The Mechanical Measurement and Quality Control module enables students to gain a solid foundation of knowledge and skill in performing measurements and calculations. The student learns to use precision measurement tools, such as steel rule, tape measure, protractor, micrometer, height gauge, various calipers and dial indicators.  The Pneumatics Technology 1 module introduces the principles of pneumatics and pneumatically controlled systems commonly used in automated manufacturing environments.

The Pneumatics Technology 1 module introduces the principles of pneumatics and pneumatically controlled systems commonly used in automated manufacturing environments.  Lubrication for Technicians conveys skills-based curriculum through virtual and hands-on activities. Students learn about lubrication equipment, application methods lubrication schedules, special purpose greases, synthetic lubricants, packing bearings and more. (Course 12 of 16 for the MSSC CPT Prep Training)

Lubrication for Technicians conveys skills-based curriculum through virtual and hands-on activities. Students learn about lubrication equipment, application methods lubrication schedules, special purpose greases, synthetic lubricants, packing bearings and more. (Course 12 of 16 for the MSSC CPT Prep Training) Introduction to Advanced Manufacturing introduces the student to the manufacturing industry and its associated career paths. Students learn about careers offered in manufacturing and about how to prepare for and then pursue those careers. (Course 13 of 16 for the MSSC CPT Prep Training)

Introduction to Advanced Manufacturing introduces the student to the manufacturing industry and its associated career paths. Students learn about careers offered in manufacturing and about how to prepare for and then pursue those careers. (Course 13 of 16 for the MSSC CPT Prep Training) This course explores the principles and techniques involved in Lean Manufacturing including minimizing waste in production and improving work flow in industrial processes. (Course 14 of 16 for the MSSC CPT Prep Training)

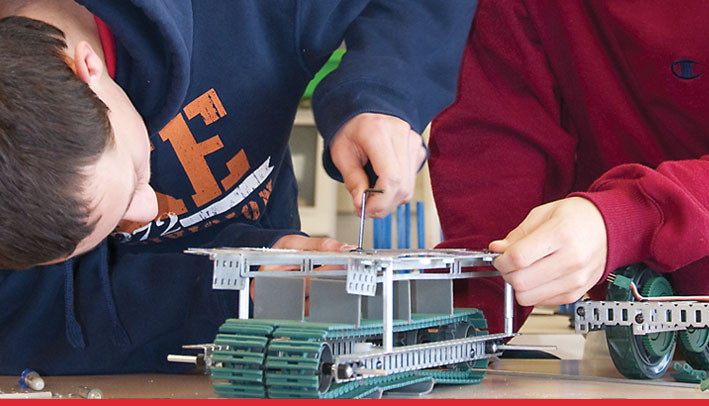

This course explores the principles and techniques involved in Lean Manufacturing including minimizing waste in production and improving work flow in industrial processes. (Course 14 of 16 for the MSSC CPT Prep Training) The Flexible Manufacturing System (FMS) module exposes students to automation and industrial applications by combining CNC technology with robotics and materials handling. Students gain "virtual hands-on" experience in CNC and robot programming, especially in I/O commands. (Course 15 of 16 for the MSSC CPT Prep Training)

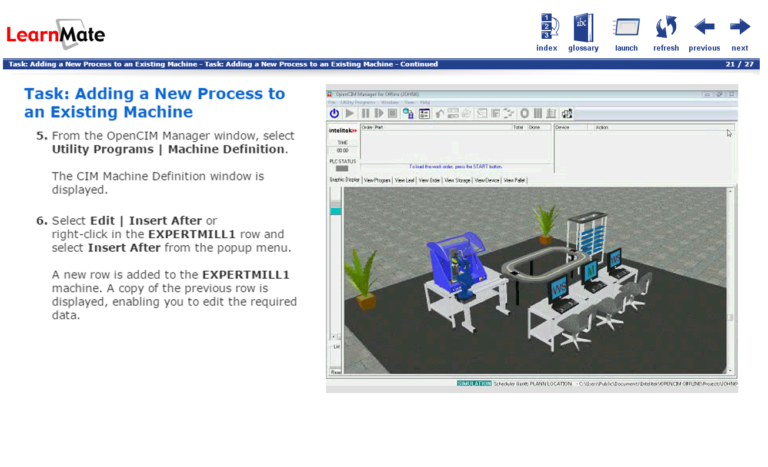

The Flexible Manufacturing System (FMS) module exposes students to automation and industrial applications by combining CNC technology with robotics and materials handling. Students gain "virtual hands-on" experience in CNC and robot programming, especially in I/O commands. (Course 15 of 16 for the MSSC CPT Prep Training) The Computer Integrated Manufacturing 1 module

The Computer Integrated Manufacturing 1 module  In the Introduction to Industrial Design course, students redesign a simple office supply product, learn and practice technical drawing techniques, and are introduced to how products are made. They explore what reverse engineering is, the importance of patents, as well as rapid prototyping. They will also use 3D design software

In the Introduction to Industrial Design course, students redesign a simple office supply product, learn and practice technical drawing techniques, and are introduced to how products are made. They explore what reverse engineering is, the importance of patents, as well as rapid prototyping. They will also use 3D design software  The Engineering Application Series (EAS) provides students the opportunity to master critical academic, workplace, and life skills while solving real-world challenges. Students solve problems by navigating the design loop process using a unique "Challenge Script” and a variety of worksheets.

The Engineering Application Series (EAS) provides students the opportunity to master critical academic, workplace, and life skills while solving real-world challenges. Students solve problems by navigating the design loop process using a unique "Challenge Script” and a variety of worksheets. Introduction to Engineering provides students an excellent overview of the field of engineering. This 20-hour course engages students with topics such as an overview of the history of engineering, career choices and the engineering design process. Multi-level hands-on activities involve product design, career seeking and ethics. To conclude the course, a capstone project challenges students to explore engineering.

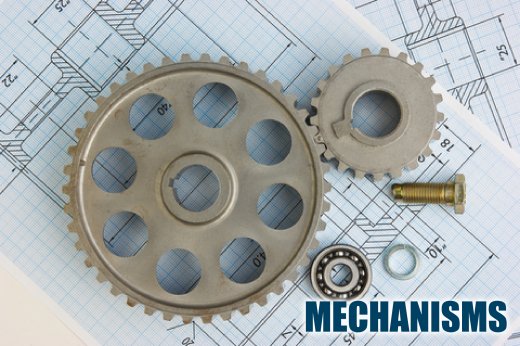

Introduction to Engineering provides students an excellent overview of the field of engineering. This 20-hour course engages students with topics such as an overview of the history of engineering, career choices and the engineering design process. Multi-level hands-on activities involve product design, career seeking and ethics. To conclude the course, a capstone project challenges students to explore engineering.  In the Mechanisms course, students examine various components of mechanisms including gears, pulleys, levers, and more. They create several of these simple machines to observe their operation first-hand. The course also instructs students on the calculation of mechanical advantage, force, friction, work, and other measurements associated with mechanisms.

In the Mechanisms course, students examine various components of mechanisms including gears, pulleys, levers, and more. They create several of these simple machines to observe their operation first-hand. The course also instructs students on the calculation of mechanical advantage, force, friction, work, and other measurements associated with mechanisms.